Hybrid Diamond & CBN Grinding Wheels

FEATURE

Hybrid Diamond/CBN Grinding Wheels

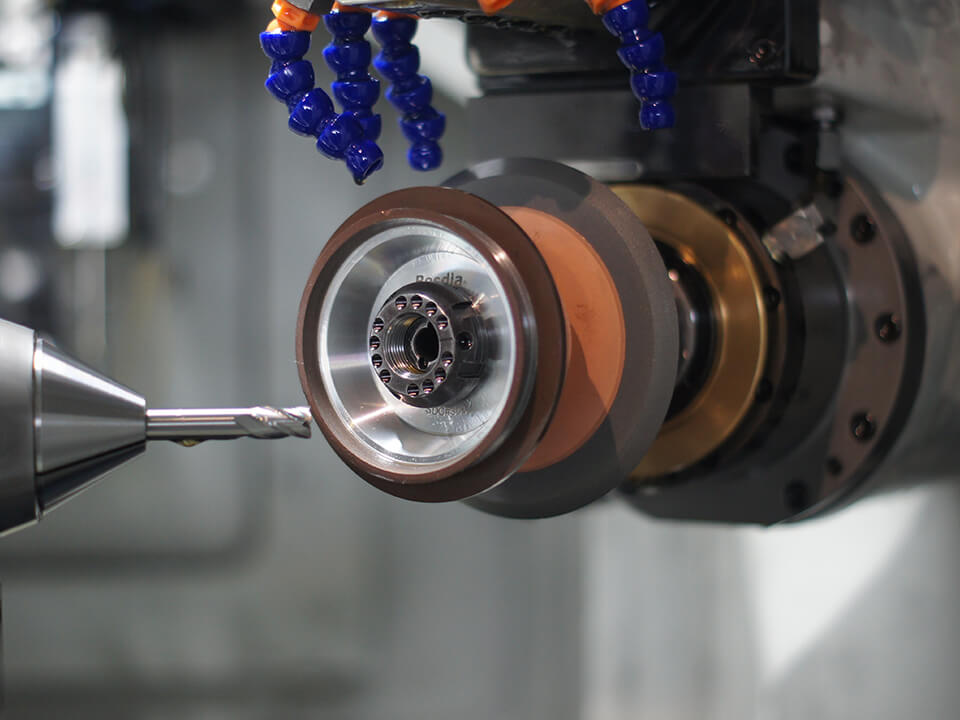

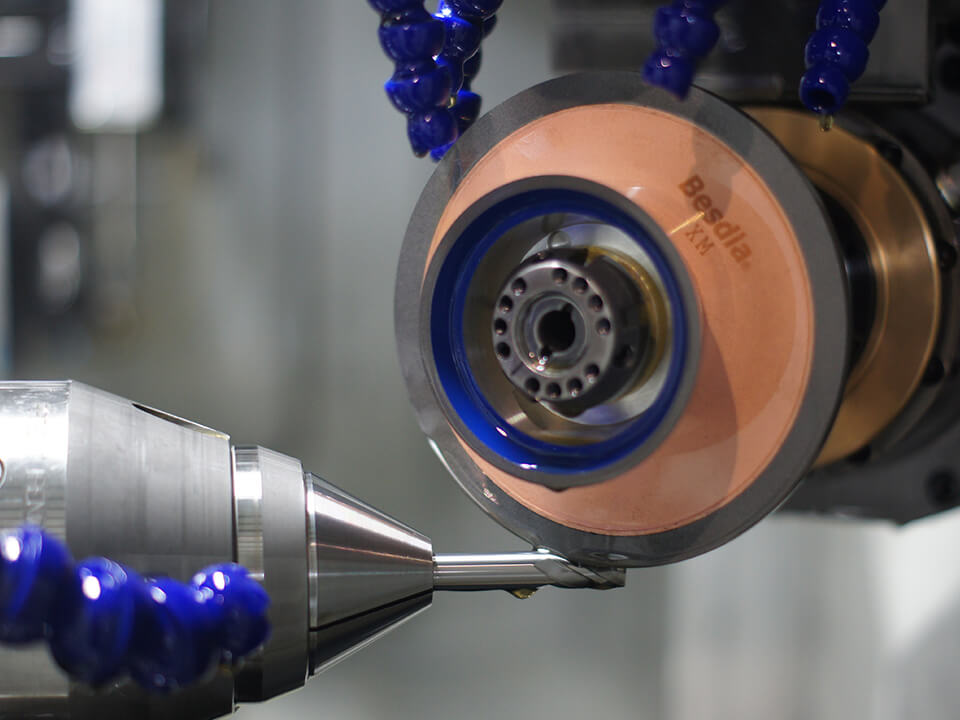

- The whole new hybrid grinding wheel in combination of multiple bonding method is mainly utilized by CNC tooling grinding machine which engages to groove and grind powerfully for carbide endmill.

It can be also used for grinding other tough and fragile materials as well as HSS and heat treatment materials.

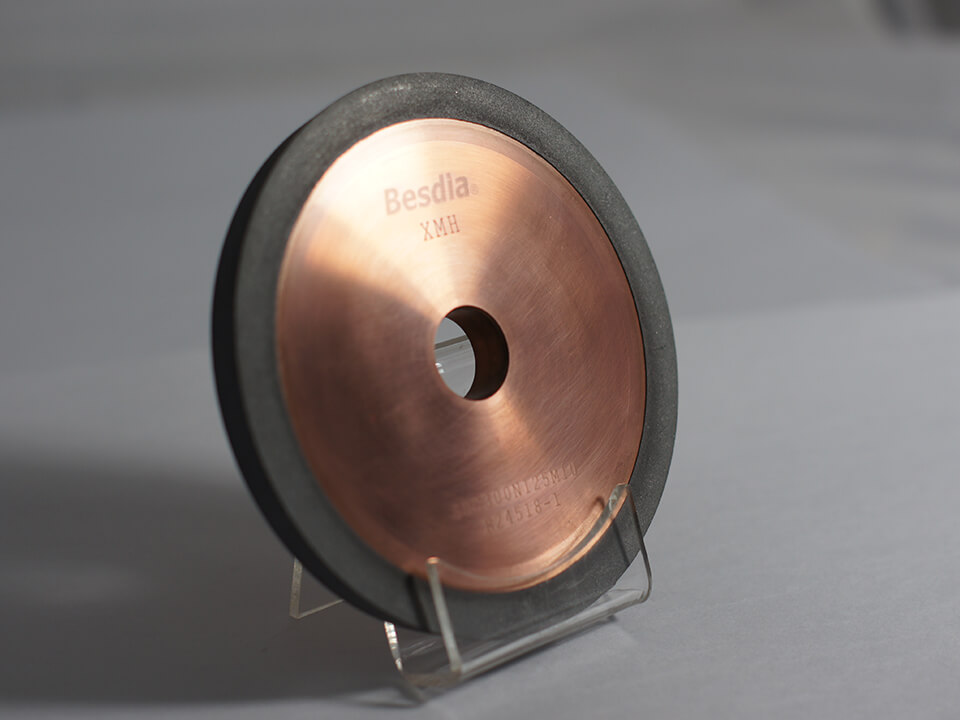

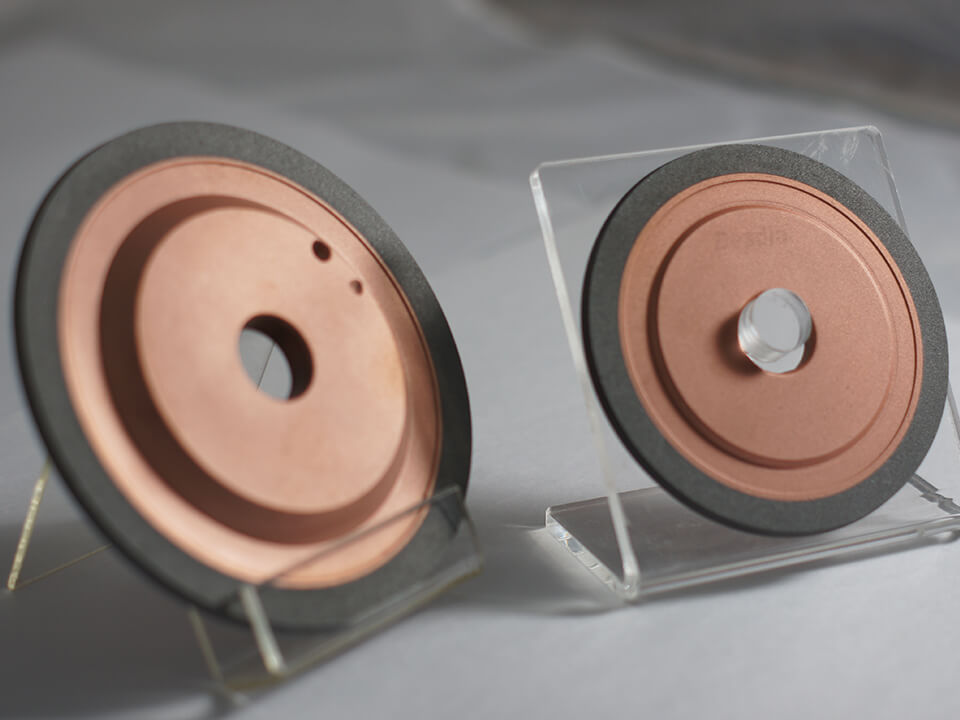

XM Hybrid Bond Grinding wheel (High Performance Fluting)

XM Hybrid Bond wheels that developed for high bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands.Its primary application is five-axis CNC tool grinding and Fluting.

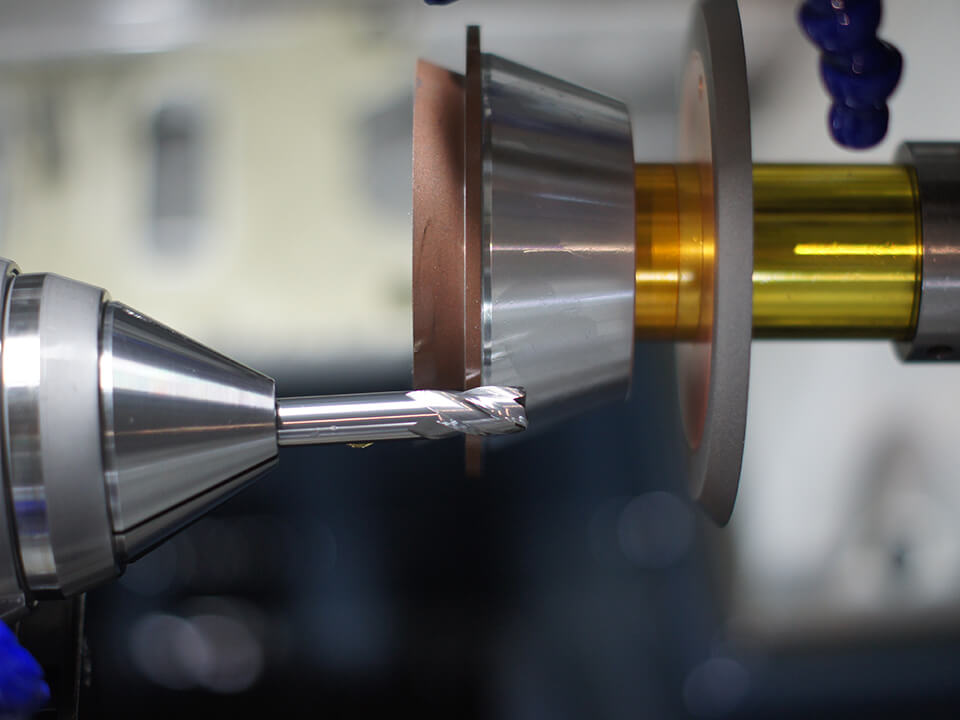

- Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

- Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

- Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

- Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.

Technical Data / Test Report

| Wheel Brand | Best Diamond Industrial Co., Ltd. | ||

| Wheel Model | Besida-XMH | Wheel Specification | SD300 |

| Wheel Number | XM-D54 | Wheel Size | 125D-10X-5U-8T-20H |

| Wheel Runout Before Grinding | 5um | Wheel Used (Flute) | 84m |

| Bond Radius Before Grinding | R0.09 | Bond Radius After Grinding | R0.25 |

| Testing Machines | Walter Helireinic Vision 400L | Grinding Parameters (S) | S=16.5(2520RPM) |

| Tool Diameter | Ø10mm | Grinding Parameters (F) | F=80(662mm/min) |

| Tool Helix Angle / Edge Length | 35 Degree / 25~50mm | Tool Material | K44/AF312 / Tungsten Carbide |

| Total Pieces of Tests | 650支 | Grinding Depth (Flute) | 1.85mm (Single Feed) |

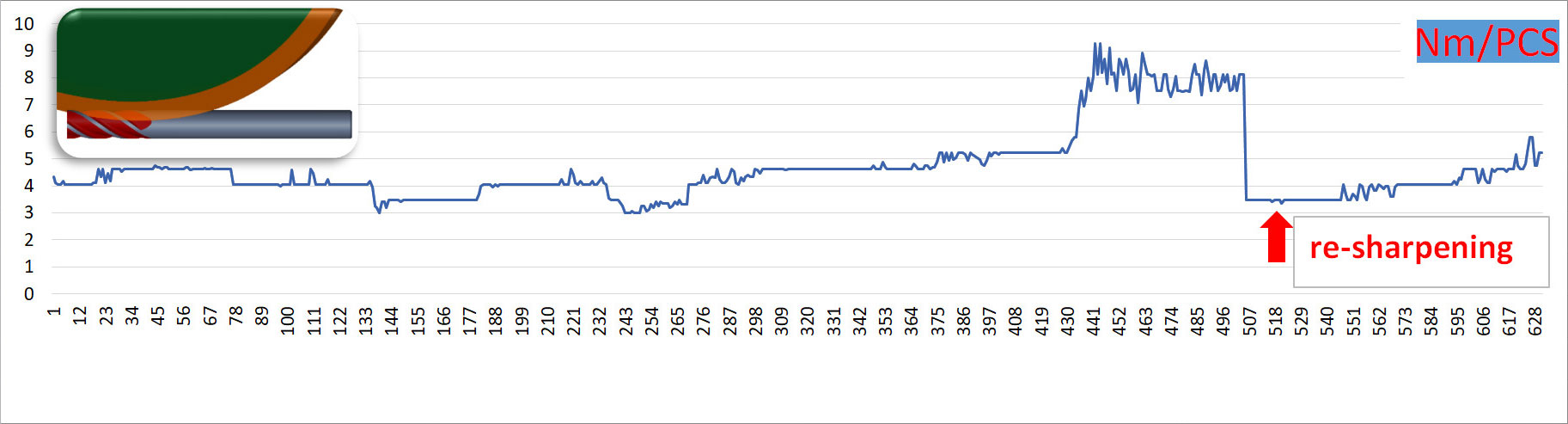

Peak Spindle Toeque